- Search Site:

- Enquiries:

+44 (0)1767 604708

Offering high stress-rupture strength and creep resistance at elevated temperatures up to 950°C(1740°F), Nimonic® 90 alloy is highly suitable for use in applications where high-temperature and high mechanical stress is a consideration.

It's derived strength is due to the addition of aluminium and titanium in the alloying process. The material offers good resistance to high-temperature corrosion and oxidation.

Nitronic 90 can be machined after full heat-treatment using conventional machining methods with commercial coolants. Higher speed machining operations (turning, milling, grinding) should be performed using water-based coolants. When boring, drilling or tapping, a heavy lubricant is required. The alloy can be formed using basic conventional techniques.

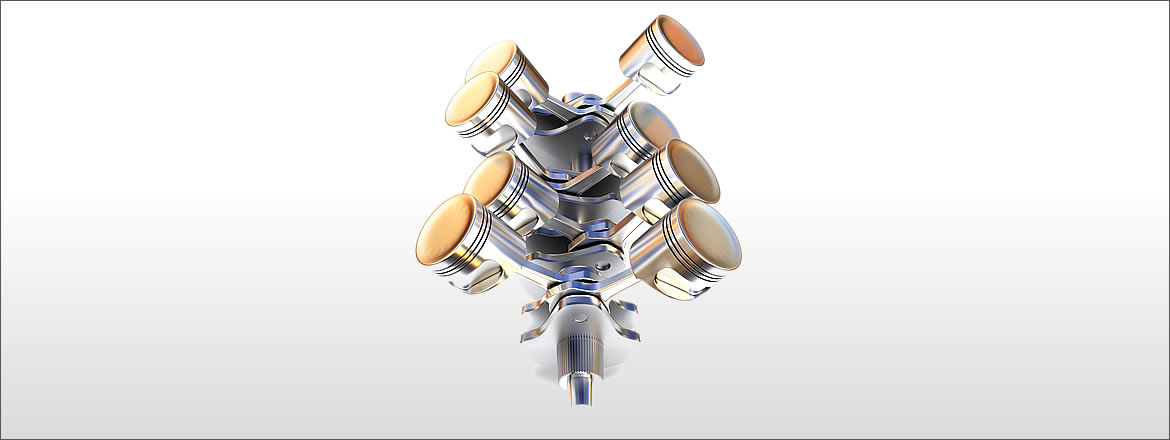

Traditionally used in the production of gas turbine blades and hot working tools, Nimonic 90 is also popular in the motorsport and automotive sector. The alloy is useful in applications where high mechanical stress and high temperature is a consideration, including specific engine applications, high-temperature springs and high-performance engine valves. The product is also a preferred choice for extreme high boost pressure turbocharged applications.

Solution treated material is suitable for welding, and a post-weld heat treatment is required to achieve optimum results. The alloy can be welded using conventional welding techniques.

Nimonic 90 is available in round bar and plate.

We are a leading stockholder and supplier of high-performance engineering materials to the motorsport sector. We are supply partners in a range of specialist motorsport markets including Formula 1, Formula E, NASCAR, MOTO GP, WEC & WRC.