- Search Site:

- Enquiries:

+44 (0)1767 604708

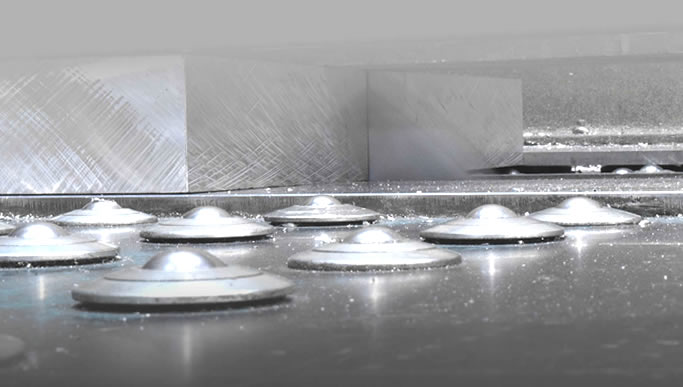

Our in-house metal processing services open up the possibility for the supply of your motorsport raw materials in sizes, lengths, finishes and coatings that are already one step closer to your exact requirements. As a value-added service, this allows you to speed up your supply considerably as it reduces component fabrication time.

We have invested millions of pounds in processing equipment and added resources to ensure that we offer everyone in the motorsport sector an unrivalled service. The benefits of utilising our processing options are various - you can avoid any unnecessary hidden costs, lead times are minimal, and our high machine utilisation makes the costs to you as low as possible.

Our metal and plastics processing options do not only relate to alloys; we also process performance plastics too.

We cut plates, rod banks and guillotine sheet to your size requirements. Other services include tube cutting, vinyl coating (where we cover your alloy sheet in a protective film) and first stage engineering, where we perform basic engineering tasks, so your material is supplied as close to the finished component as possible. Our processing services will save you time & money.

Many of our motorsport customers find it inefficient to manufacture down to size. Essentially what we do is all the leg work for you. The beauty of our processing services is not only the scale and variety of service that we offer but the fact that we are also BSI accredited too. Taking advantage of our added-value services will allow you to get on with the more critical, complicated manufacturing processes that earn you money.