- Search Site:

- Enquiries:

+44 (0)1767 604708

INCONEL® nickel-chromium alloy 625 promotes high strength, excellent fabricability (including joining), and outstanding corrosion resistance.

Service temperatures range from cryogenic to 1800°F (982°C). The strength of nickel alloy 625 draws from the stiffening effect of molybdenum and niobium on its nickel-chromium matrix; hence, there is no requirement for precipitation-hardening treatments. This combination of elements is responsible for superior resistance to a wide range of corrosive environments of unusual severity as well as to high-temperature effects such as oxidation and carburization. Tests in geothermal brines indicate that Alloy 625 is highly resistant to hot geothermal fluids comparable to titanium grade 2.

Tests in simulated flue gas desulfurization environments show that Alloy 625 is highly resistant to environmental atmospheres in comparison to alloys such as T316 stainless steel and comparable to Alloy C276.

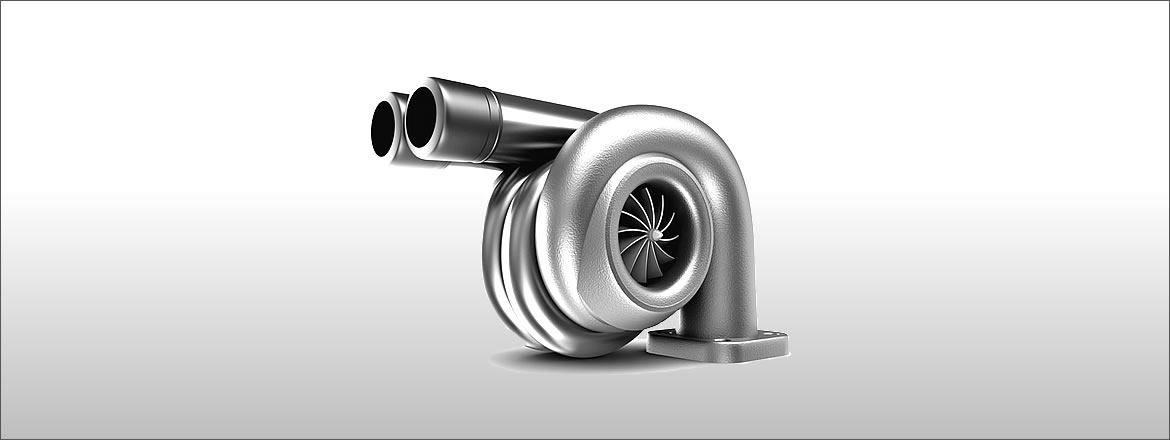

Motorsport applications for Inconel 625 include:

We are a leading stockholder and supplier of high-performance engineering materials to the motorsport sector. We are supply partners in a range of specialist motorsport markets including Formula 1, Formula E, NASCAR, MOTO GP, WEC & WRC.