- Search Site:

- Enquiries:

+44 (0)1767 604708

The alloy is the most widely used high strength titanium. Ti-6Al-4V (Grade 5) combines mechanical strength and low density (4.42 kg/dm³) with excellent corrosion resistance in many different environments. Grade 5 titanium is heat treatable (solution heat treatment plus ageing) in sections up to 25mm and can be employed up to around 400°C.

We stock this alloy in the following: bar, wire sheet, extrusions, forgings, seamless pipes and tubes.

The alloy can be machined using practices for austenitic steels with slow speeds, heavy feeds, rigid tooling and large amounts of non-chlorinated cutting fluid.

The alloy benefits from good weldability in the annealed condition or the solution and partially aged condition, with ageing completed during the post-weld heat treatment. Precautions must be taken to prevent oxygen, nitrogen and hydrogen contamination. Fusion welding by inert gas welding of the molten metal and the adjacent heated zones using a trailing shield is acceptable. Other welding practices include spot, seam and flash welding performed without resorting to protective atmospheres.

Market applications for Grade 5 Titanium include:

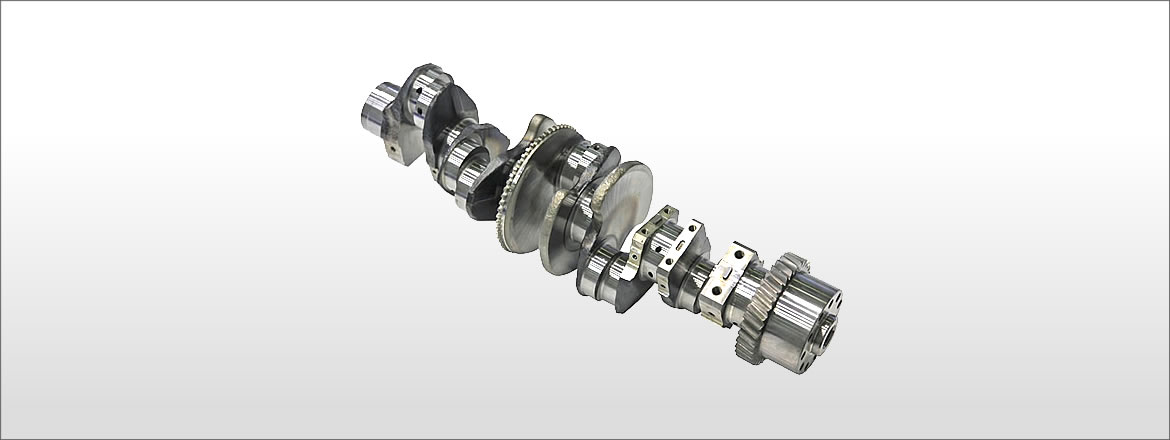

We are a leading stockholder and supplier of high-performance engineering materials to the motorsport sector. We are supply partners in a range of specialist motorsport markets including Formula 1, Formula E, NASCAR, MOTO GP, WEC & WRC.