- Search Site:

- Enquiries:

+44 (0)1767 604708

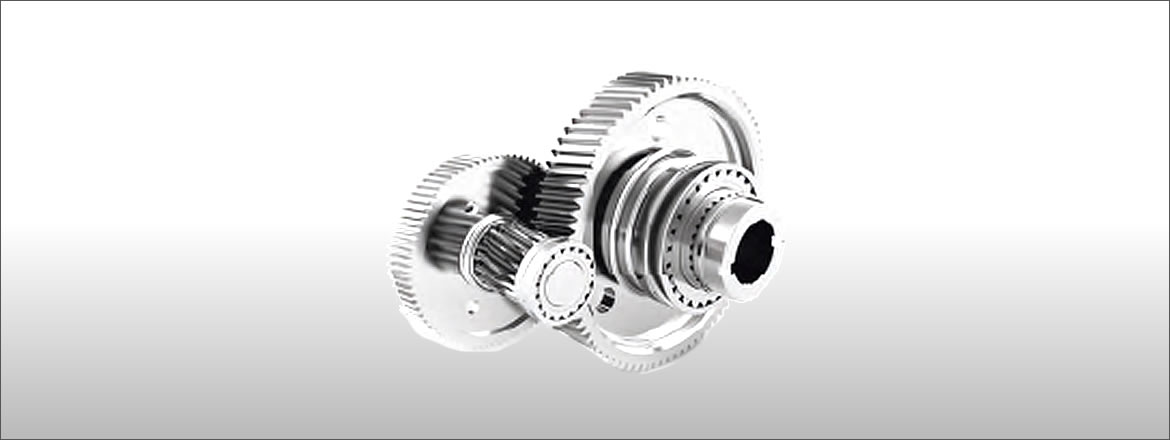

Increased engine power transmission demands high-performance gears.

The design objective was to develop a secondary hardening gear and bearing steel with superior core and surface properties to current gear steels. Ferrium® C64 is a member of a new class of martensitic secondary hardening gear and bearing steels that utilise an efficient M2C precipitate strengthening dispersion. Because of the efficiency of this strengthening dispersion, Ferrium® C64 achieves carburised surface hardness (62-64 HRC) superior to current gear steels with the added benefit of increased core properties.

Designed for high-temperature carburising and allowing solution heat and carburising treatment to be combined, the steel is quenched directly from the carburising temperature.

After quenching to room temperature, it is subjected to cryogenic treatment to assure a complete martensitic transformation. Tempered at 925°F (496°C), Ferrium® C64 offers excellent thermal resistance approaching this temperature. Case carburising produces a gradient in the volume fraction of the M2C carbides and results in an increase in hardness and surface residual compressive stress.

The efficiency of the M2C strengthening response allows the steel to achieve very high surface hardness while keeping carbon content low and without the formation of detrimental primary carbides. We recommend final shot peening for superior fatigue performance.

We are a leading stockholder and supplier of high-performance engineering materials to the motorsport sector. We are supply partners in a range of specialist motorsport markets including Formula 1, Formula E, NASCAR, MOTO GP, WEC & WRC.